- Solar Outdoor Lighting

- Integrated Solar Street Lights

- Solar lighting

- Supplier in China

- Solar Garden Light manufacturer

- All in One Solar Street Lamp

- Integrated solar street lights and semi solar road

- LED Rechargeabl Floodlight with Bluetooth

- The Development Trend of Solar Energy Industry

- Low-light charging + ultra-long battery life! Solar street lights, 3 hours of sunlight for a whole week, with unrivaled battery life

- Intelligent light control + human body sensing, solar street lights: lighting on demand saves more power, and full performance details

- 15 meters ultra-long illumination + IP67 waterproof solar street light: hard-core performance covers all outdoor scenarios

- Conversion rate increased by 39%! High-efficiency crystalline silicon solar street lights, 6 hours of sunlight for the whole night

- How to maintain the solar street light panels?

- solar street light

- Integrated Solar Street Light

- All in One solar street light

- Solar Led Street Light

- Solar Street Light Factory

- Integrated Solar Parking Lot Lights

- Integrated Solar Billboard Lights

- China Solar Lighting Supplier

- All In One Solar LED Street Lamp

- Outdoor Waterproof Solar Road Lighting

Categories

New blog

Tags

- 2025-04-18 18:24:41

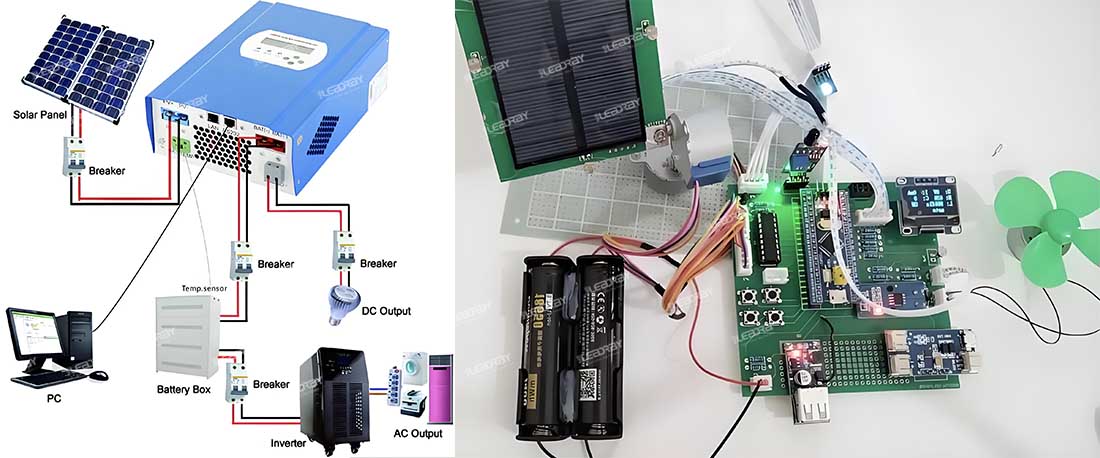

Photoelectric test is the cornerstone of solar street lamp performance test. In a professional optoelectronic test laboratory, simulators can realistically reproduce a wide range of global light conditions, from intense direct light at the equator to low-angle diffuse light at high latitudes. Through high-precision power analyzer, illuminometer and other equipment, the photoelectric conversion efficiency of solar panels under different light intensity and Angle is accurately measured.

Only when the solar panel can stably and efficiently convert light energy into electricity in a variety of simulated environments, and the conversion efficiency meets or exceeds the industry standard, can it enter the next production process to ensure that the street lamp can continue to supply power to the system in a variety of climate and lighting conditions in Nigeria.

2. Controller aging test: stable operation guarantee

The controller is like the "intelligent brain" of the solar street lamp, and its reliability is crucial. In the burn-in test shop, extreme conditions are simulated through the burn-in test system. The controller is placed in a high temperature (such as 60 ° C, simulating the hot summer in Nigeria), high humidity (above 75% RH, corresponding to some coastal humid areas) environment, while allowing it to execute uninterrupted charge and discharge, lighting time control and other commands, and continue to run for thousands of hours. During this period, the parameters of the controller are monitored in real time, and the fault or parameter drift is investigated immediately. Such a rigorously aged controller can precisely control the operation of street lights in Nigeria's complex and changeable natural environment, ensuring stable and efficient operation of the system.

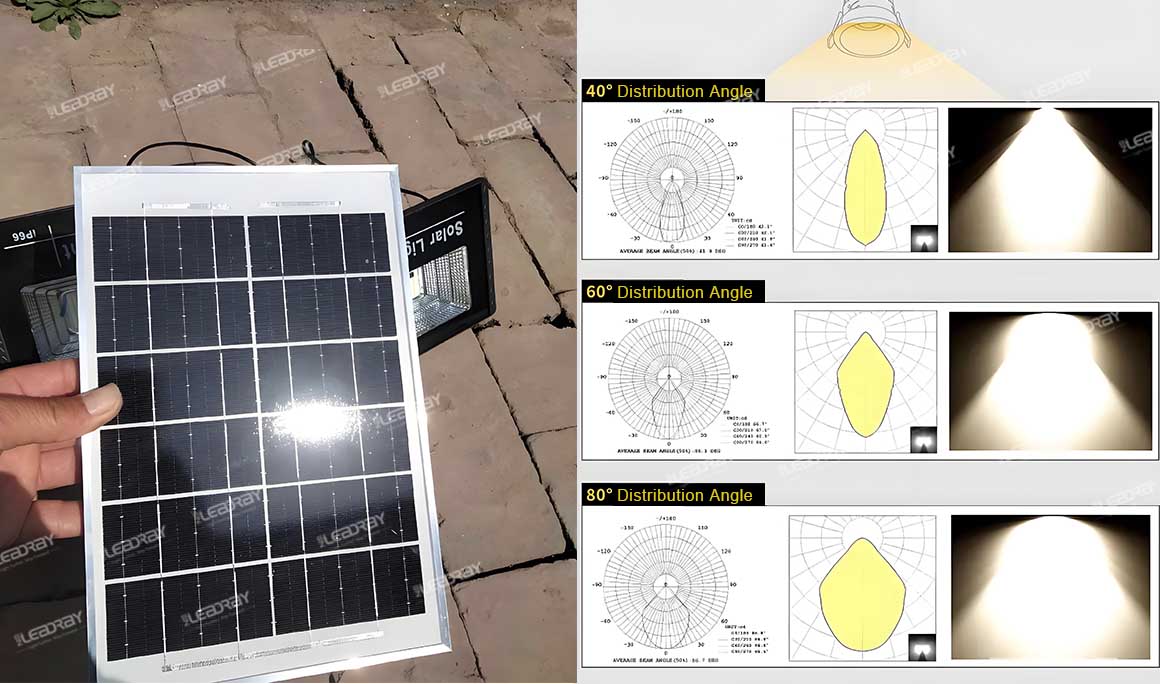

3.Third, LED light deployment: lighting experience optimization

The deployment of LED lights is related to the lighting quality of solar street lights. Professional optical engineers use advanced spectral analyzers, integrating spheres and other equipment to fine-tune the color temperature, color rendering index and luminous flux of LED lights. According to different application scenarios, such as the urban main road needs high brightness and high color rendering index to ensure traffic safety, the color temperature is usually allocated to 4000K-5000K; Rural roads pay more attention to soft lighting to avoid light pollution, and the color temperature can be controlled at 3000K-4000K. Through the optimization of LED lamp bead arrangement and lens design, to ensure the uniform distribution of lights, no glare, dark areas, to provide a comfortable and safe night lighting environment for urban and rural roads in Nigeria.

4.Fourth, base material: stable and durable foundation

The base material of the solar street lamp directly determines its service life and safety. We use high-strength, corrosion-resistant Q345B steel, which has a high yield strength and can withstand the heavy force of street lamps in severe weather conditions such as strong winds (which can hit parts of Nigeria in cyclones). At the same time, the steel surface is hot-dip galvanized, and the thickness of the galvanized layer reaches more than 80μm, which can effectively resist the erosion of Nigeria's humid and salty air and prevent rust. In addition, for special corrosion environments such as coastal areas, spray protection will also be carried out on the basis of hot dip galvanizing to further improve the corrosion resistance of the base, to ensure that the base of the street light in various complex geographical environments in Nigeria, long-term stable support of the lamp body, to ensure the normal operation of the street light.

We are very much looking forward to further communication with you, work together to create a better solar street lamp project, and jointly explore the Nigerian solar street lamp market.

Language

Language English

English français

français العربية

العربية 中文

中文 sales@szleadray.com

sales@szleadray.com +86-13424390319

+86-13424390319