- Solar Outdoor Lighting

- Integrated Solar Street Lights

- Solar lighting

- Supplier in China

- Solar Garden Light manufacturer

- All in One Solar Street Lamp

- Integrated solar street lights and semi solar road

- LED Rechargeabl Floodlight with Bluetooth

- The Development Trend of Solar Energy Industry

- Low-light charging + ultra-long battery life! Solar street lights, 3 hours of sunlight for a whole week, with unrivaled battery life

- Intelligent light control + human body sensing, solar street lights: lighting on demand saves more power, and full performance details

- 15 meters ultra-long illumination + IP67 waterproof solar street light: hard-core performance covers all outdoor scenarios

- Conversion rate increased by 39%! High-efficiency crystalline silicon solar street lights, 6 hours of sunlight for the whole night

- How to maintain the solar street light panels?

- solar street light

- Integrated Solar Street Light

- All in One solar street light

- Solar Led Street Light

- Solar Street Light Factory

- Integrated Solar Parking Lot Lights

- Integrated Solar Billboard Lights

- China Solar Lighting Supplier

- All In One Solar LED Street Lamp

- Outdoor Waterproof Solar Road Lighting

Categories

New blog

Tags

- 2025-07-10 18:31:07

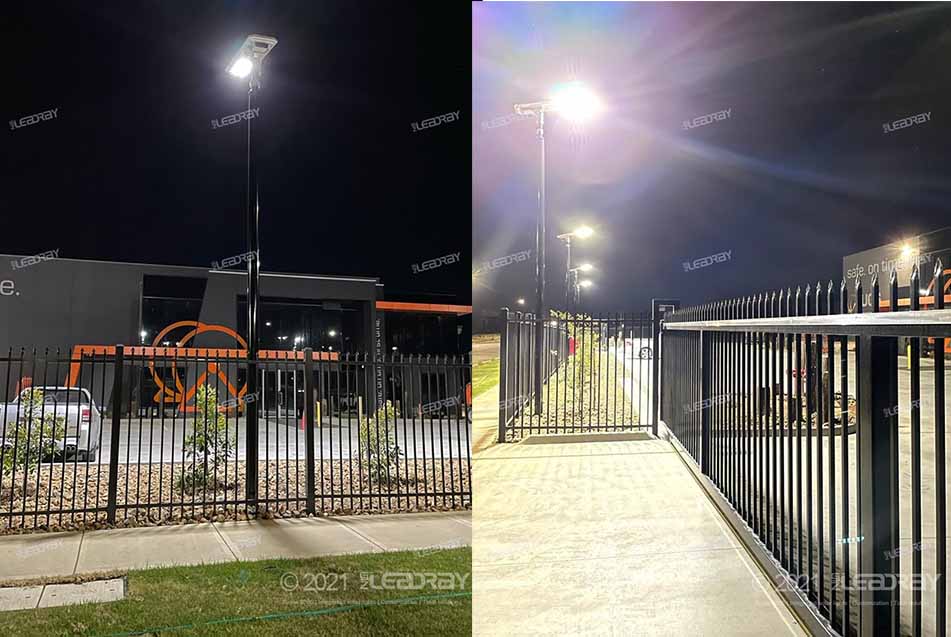

Outdoor solar street lamps in industrial parks are lighting devices specially designed for outdoor environments in industrial areas. Combining solar power generation technology, they feature energy conservation, environmental friendliness, and flexible installation.

They can meet the night lighting needs of areas such as park roads, surrounding factory areas, parking lots, and peripheral warehouses.

The following details are provided from aspects such as core composition, advantages and features, selection points, and maintenance suggestions:

1. Power Generation Component Core Composition

The working system of industrial park solar street lamps is composed of several key components to ensure stable lighting:

Solar panels: The core power generation component, usually made of single-crystal silicon or polycrystalline silicon, with single-crystal silicon having a higher conversion efficiency (18%-23%), suitable for areas with average lighting conditions; polycrystalline silicon has a lower cost and performs stably in strong light environments.

The panels need to have characteristics of resisting wind, hail, and high and low temperatures (-40°C to 70°C), adapting to the complex climate of industrial parks.

Energy storage batteries: Store the electricity generated during the day for use at night. Commonly used are lead-acid batteries (low cost, suitable for areas with small temperature differences) and lithium batteries (small in size, long lifespan, better low-temperature performance, recommended for industrial parks to prioritize), with capacity designed based on lighting duration, power requirements, and reserve for rainy days, generally needing to meet 3-7 days of continuous rainy lighting.

Ordering of lighting fixtures for industrial park LED light sources: The core of lighting, featuring low energy consumption, high brightness, and long lifespan (50,000 - 100,000 hours).

Industrial parks need to choose high color rendering index (Ra≥70) and color temperature 3000K - 5000K light sources (3000K warm white light is suitable for the surrounding living areas, 5000K cold white light is suitable for main roads and work areas, with higher recognition), and need to have anti-glare design to avoid affecting nighttime work safety.

Smart controllers: Responsible for coordinating the work of the solar panels, batteries, and light sources, with functions such as light control (automatically turns on at night), time control (setting lighting duration, such as 18:00 - 24:00 fully lit, reducing power after midnight for energy conservation), overcharge and overdischarge protection (to extend battery life), reverse connection protection. Some high-end models support remote monitoring (via GPRS/4G to check battery level and fault warnings).

Light poles and foundations: The light poles are mostly made of hot-dip galvanized steel pipes (durable and long-lasting, with a lifespan of 15-20 years), the height is selected based on the lighting area (main roads 8-12 meters, secondary roads 6-8 meters, factory edge 4-6 meters), with a wall thickness of ≥3mm to resist strong winds (must meet the local wind resistance level, such as ≥12 levels in coastal areas). The foundation is made of concrete pouring, the depth is determined based on the light pole height and geological conditions (generally 0.8-1.5 meters), to ensure stability against overturning.

2. Ordering of lighting fixtures for industrial park Core Advantages of Industrial Park Scenarios

Zero electricity cost and energy conservation: Completely relying on solar power generation, no need to connect to the power grid, especially suitable for areas in industrial parks far from the power grid (such as warehouse peripheries, raw material storage areas), long-term use can significantly reduce electricity costs and reduce cable laying costs.

Flexible installation:Not restricted by power grid lines, simply choose a location with sufficient sunlight (avoid being blocked by buildings or large trees), the installation period is short (a single lamp can be completed within 1-2 days), suitable for park expansion and temporary lighting needs.

Safe and reliable: Using low-voltage direct current power supply (12V/24V), avoiding the risk of high-voltage electric shock, especially safer in humid and dusty industrial environments; no open flames, no fire hazards caused by aging power lines.

Low maintenance cost: Core components (batteries, light sources) have long lifespans (lithium batteries 5-8 years, LED light sources over 50,000 hours), no frequent maintenance required, only need to clean the solar panels regularly (remove dust, bird droppings to ensure power generation efficiency). Environmental protection and policy alignment: Zero carbon emissions, in line with the national "dual carbon" policy. In some areas, there are subsidies for industrial energy-saving projects; and it can still operate normally during power outages, ensuring the safety of the park at night (such as security patrols, emergency passage lighting).

3.Selection Key Points (Based on the needs of industrial parks)

Lighting and power matching

The power of the solar panel and the capacity of the battery need to be selected based on the average annual sunshine duration in the local area: For example, in northern regions (average annual sunshine of 3-4 hours), if the power of the street lamps is 60W, a 18V 150W solar panel + 12V 100Ah lithium battery needs to be selected to ensure normal lighting for 3 consecutive rainy days.

Resistance to harsh environments

Wind resistance and earthquake resistance: The lamp pole needs to pass mechanical calculations to ensure stability in strong winds and earthquakes, and the connection components (such as flanges) need to be welded firmly and treated for anti-corrosion.

4.Industrial park outdoor solar street lamps Lighting demand matching

Lighting mode: It is recommended to adopt "intelligent dimming" (such as full brightness for the first 4 hours, and reduced to 50% power in the late night), taking into account both lighting needs and energy conservation, and extending battery life during rainy days.

Priority should be given to brands with industrial lighting experience (such as Philips, Oupu's industrial series, or brands focusing on solar energy such as Sunlight Lighting, Huayi Lighting), to ensure component quality (batteries use electric cells from major manufacturers such as Ningde Times and BYD, controllers have overload protection functions).

After-sales should include: battery warranty of more than 5 years, lamp pole warranty of 10 years, and provide local maintenance services (industrial park equipment failures need to be responded to quickly to avoid affecting production safety).

5. Industrial park lighting for agricultural purposes Maintenance and Precautions

Regular cleaning: Clean the surface of the solar panel every 1-3 months (use a soft cloth or high-pressure water gun, avoid scratching the glass), especially in parks with heavy dust and frequent smog, it can increase 10%-30% of power generation.

Battery inspection: Check the connection lines of the battery every year for looseness or bulging (lead-acid batteries need to pay attention to the electrolyte level, lithium batteries do not need maintenance), and replace them in time to avoid affecting the overall lifespan.

Light source and controller: If there is a sudden drop in brightness or no light, first check if the controller is faulty (such as the over-discharge protection is triggered), then check if the light source is damaged (a single LED light bulb damage can be replaced separately, no need to replace the entire lamp);

Anti-obstruction: Regularly check if there are any new obstructions around the lamp pole (such as new buildings, trees growing), promptly clear or adjust the position of the lamp pole to ensure that the solar panel receives at least 4 hours of direct sunlight every day.

Industrial park outdoor solar street lamps

Ordering of lighting fixtures for industrial park

Industrial park lighting for agricultural purposes

Market for ordering of industrial park street lamps

6.Market for ordering of industrial park street lamps Examples of applicable scenarios

Perimeter walls of the factory area, security patrol roads (6-8 meter lamp pole, 30-50W power, combined with surveillance camera lighting);

Raw materials / finished goods storage areas, parking lots (4-6 meter lamp pole, 50-80W power, illuminating vehicle loading and unloading, goods counting areas);

Emergency passages, fire passages (low-power constant lighting mode to ensure basic lighting during night evacuation).

Helen Fu: +86 134 2439 0319

Gary Zhou: +86 181 2706 1312

Language

Language English

English français

français العربية

العربية 中文

中文 sales@szleadray.com

sales@szleadray.com +86-13424390319

+86-13424390319