Happy New Year 2026!

Thank you for your sincere collaboration over the past year. May we continue to gallop forward, ride the wind and waves, and achieve greater success in the Year of the Horse.

As the old year draws to a close and the new year dawns, we bid farewell to the extraordinary 2025 and usher in the promising 2026. On this joyous occasion of celebrating the New Year, Shenzhen Leadray extends our most sincere greetings and warmest wishes to all our valued customers, partners, industry colleagues, and every employee who has been striving with us! May the new year bring you peace, prosperity, and boundless opportunities.

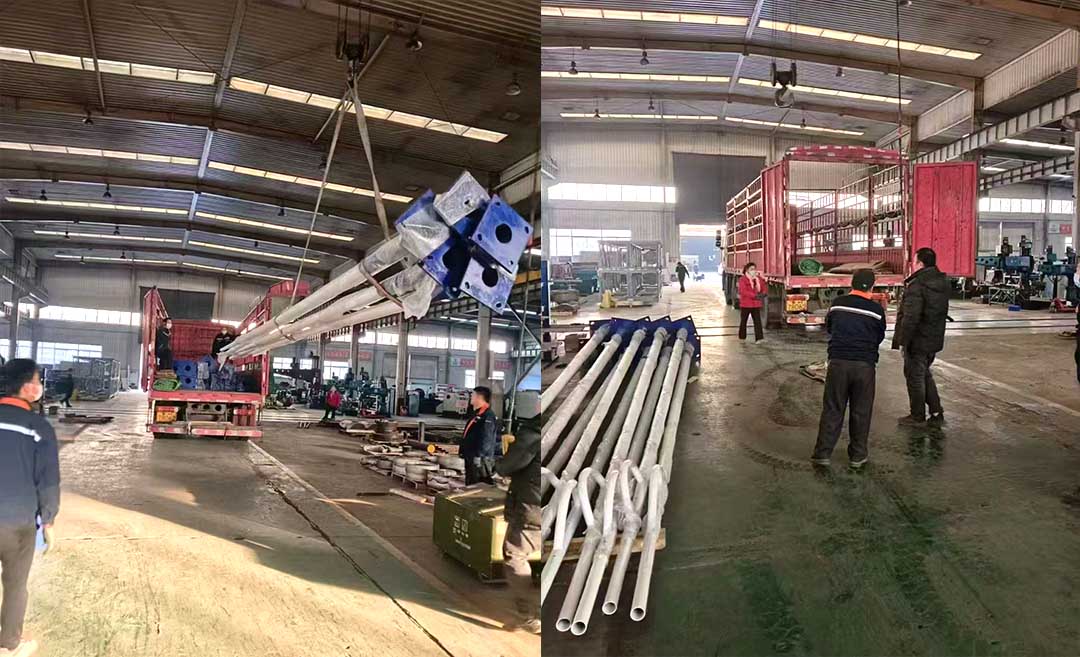

Looking back on 2025, it was a year of joint exploration and fruitful achievements in the smart street light industry. Guided by national policies on smart city construction and green low-carbon development , Shenzhen Leadray has always adhered to the concept of "technology-driven, quality-first", focusing on the R&D and innovation of smart street light products.

We have continuously promoted the integration of advanced technologies such as 5G-A, edge computing, and AI with street light infrastructure , successfully launching a series of high-performance products featuring energy conservation, intelligence, and multi-scenario adaptation.

Our products have been widely applied in urban roads, industrial parks, digital villages, and other fields, contributing to improving urban management efficiency, reducing energy consumption, and building a safer and more convenient living environment for communities .

This year, we have witnessed the industry transform from "pilot demonstration" to "large-scale replication" , and we are deeply grateful for the trust and support from all walks of life. Whether it is the close cooperation with partners in project co-construction, the recognition from customers for our product quality and after-sales service, or the hard work and dedication of every Leadray person, these have become the strong driving force for us to move forward.

Every street light we light up is not only a symbol of brightness, but also a witness to our joint efforts in promoting the development of the smart city industry.

As we step into 2026, a new journey full of hope and challenges awaits us.

The smart street light industry will usher in broader development prospects with the continuous advancement of new infrastructure and the deepening of urban digital transformation .

Shenzhen Leadray will continue to take technological innovation as the core, focus on the research and development of key technologies such as full-environment adaptive design, "space-air-ground" collaborative sensing, and intelligent operation and maintenance , and strive to provide more efficient, environmentally friendly, and intelligent street light solutions for global customers.

We will also actively respond to the call of the "double carbon" goal, promote the application of green energy technologies such as solar energy in street light products , and make greater contributions to building a low-carbon and sustainable smart city ecosystem.

The new year, new hopes, new journeys.

In 2026, Shenzhen Leadray is willing to join hands with all partners to seize development opportunities, meet challenges head-on, and work together to write a new chapter in the smart street light industry. We will live up to expectations, keep moving forward, and use better products and services to illuminate the way forward for urban development and bring more warmth and convenience to people's lives.

Once again, wish you and your family a happy New Year, good health, smooth work, and all wishes come true!

Shenzhen Leadray Optoelectronic Co., Ltd.

December 2025

Read More

IPv6 network supported.

IPv6 network supported.