[The Full-Process Connection Between Solar Street Light Factory Products and IEC]

From product design to mass production quality inspection to market delivery, IEC standards permeate the entire factory production chain and are a core guarantee of product compliance and reliability:

1. Product Design Phase: Use IEC as the "Design Red Line"

The factory's R&D department must integrate IEC standards into the design process to avoid late-stage rectification costs:

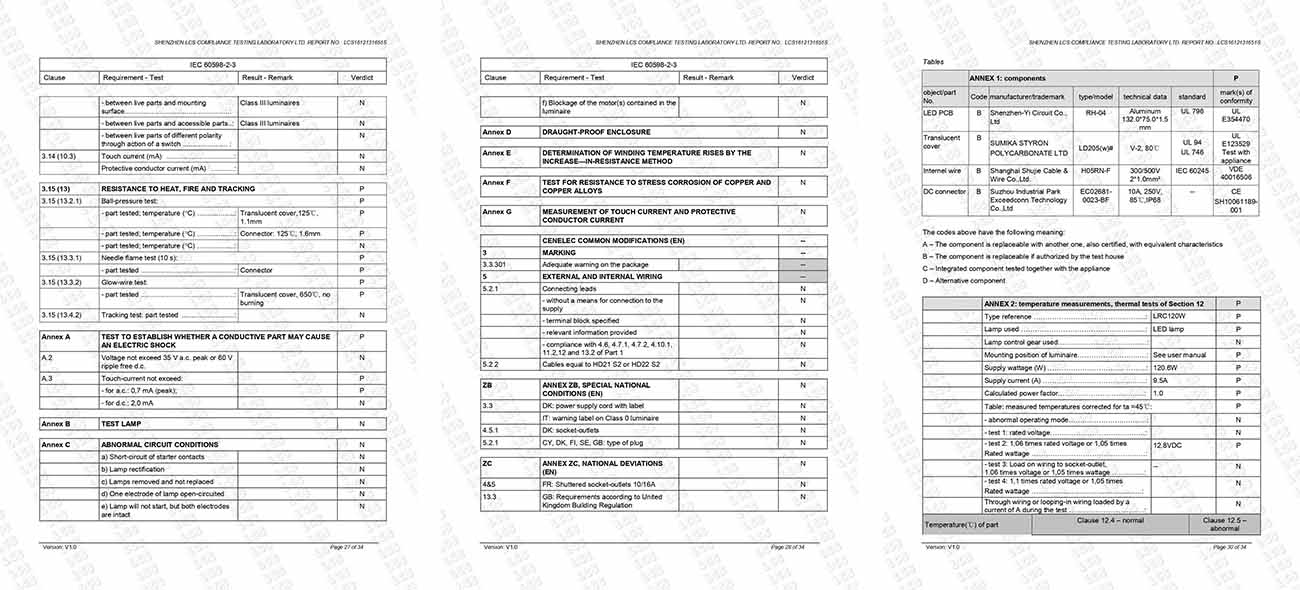

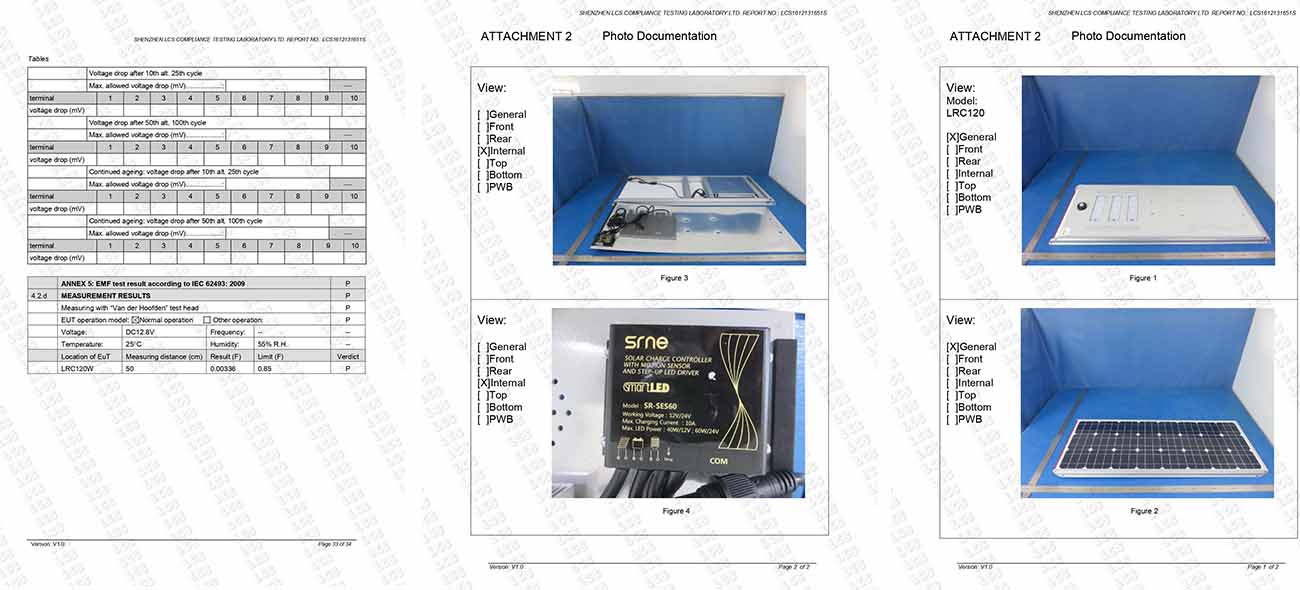

Component Selection: For example, when selecting photovoltaic panels, confirm that the supplier's products are compliant with IEC 61215 certification.

When selecting lithium batteries, they must meet the overcharge and short-circuit protection requirements of IEC 62133 and provide a third-party test report.

Circuit Design: The controller circuit must comply with IEC 61347-2-13 (a special safety standard for LED controllers).

For example, a surge protector (withstands 10kV lightning strikes) must be added to the AC input and an overcurrent protection fuse (fusing current ≤ 1.5 times the rated current) must be added to the battery circuit.

Structural Design: The luminaire housing must comply with IEC 61347-1 The design requires a waterproof structure (waterproof rating ≥ IP65, IP67 required for some rainy areas), and the casing material must pass the glow-wire test (no fire after contact with a 960°C hot wire for 30 seconds).

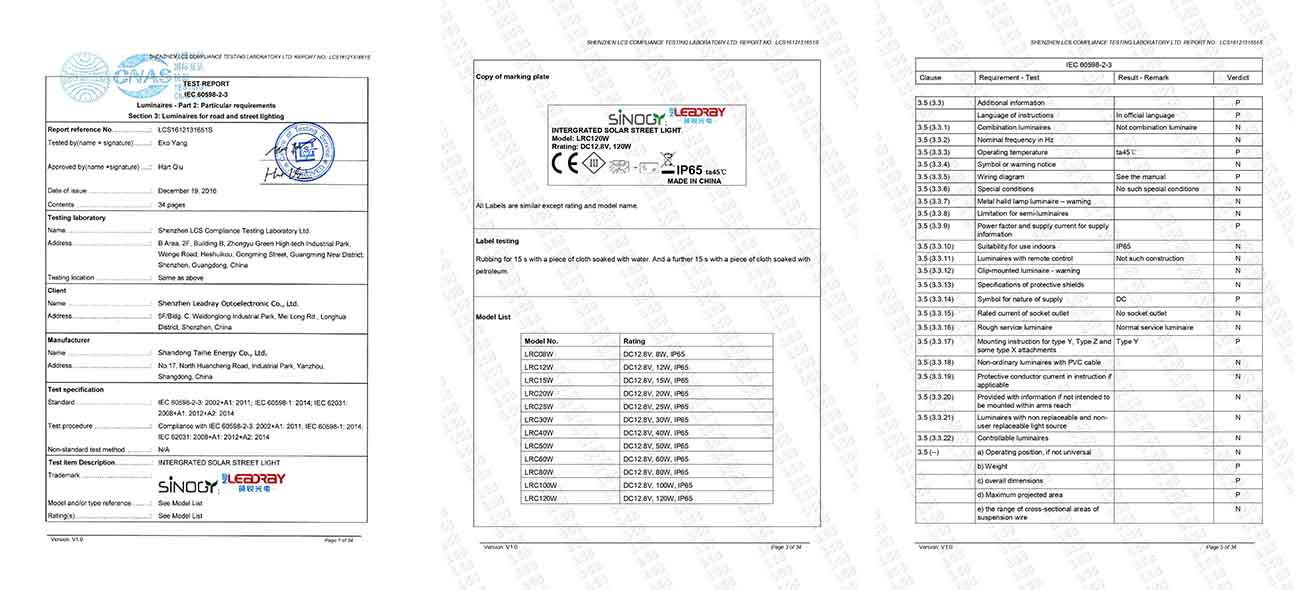

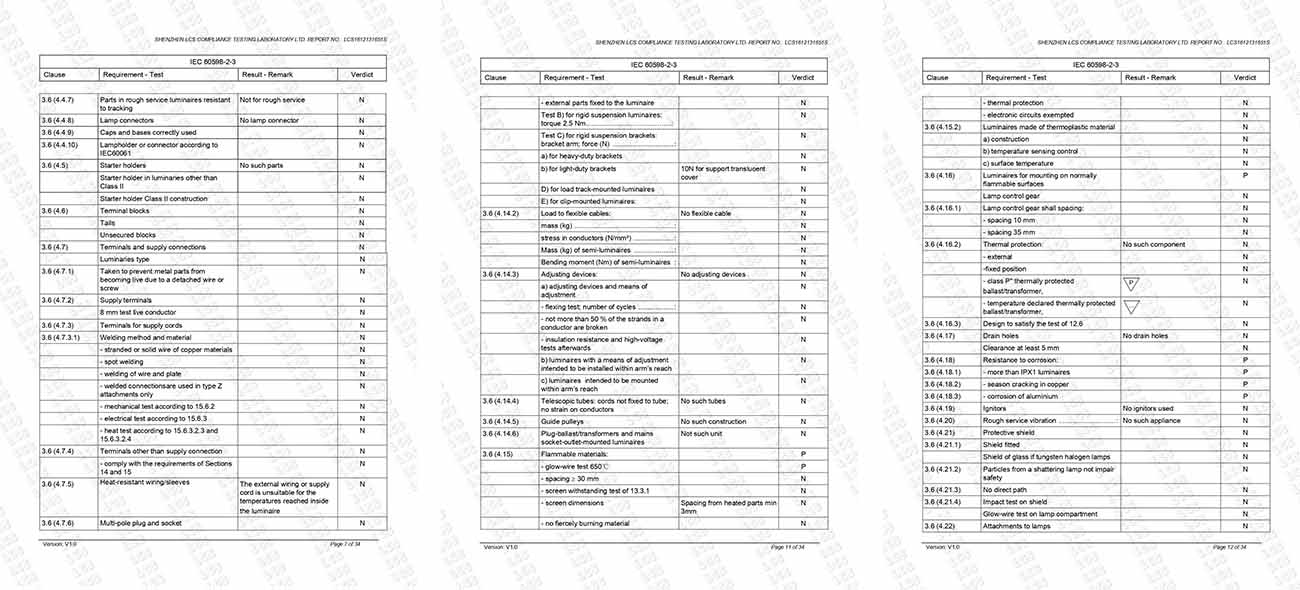

2. Production Quality Inspection: IEC standards are used as the "Qualification Criteria."

The factory must establish an electrical safety laboratory and EMC testing room that comply with IEC standards and conduct "full inspection" and random inspections on all products.

Full factory inspection items (mandatory for every product):

Insulation resistance test: Use a 500V megohmmeter to measure the insulation resistance between the lamp housing and the power terminal. The test must be ≥2MΩ (in compliance with IEC 61347-1).

Ground continuity test: Use a 25A current to measure the ground resistance between the ground terminal and the housing. The test must be ≤0.5Ω (to avoid the risk of electric shock).

Batch random inspection items (3% of each batch, with a minimum of 5 units):

Lithium battery safety test: Overcharge test according to IEC 62133 (charge to 1.2 times the rated voltage for 24 hours). No fire or leakage is observed.

EMC test: Test the product's electromagnetic emissions in an EMC darkroom (in compliance with IEC 62133). 61000-6-3) to avoid interference with surrounding equipment.

Weatherproof testing: The luminaire was subjected to high and low temperature cycling (-25°C to +55°C, 20 cycles) in accordance with IEC 61347-1. After testing, the luminaire was able to illuminate normally with no parts falling off.

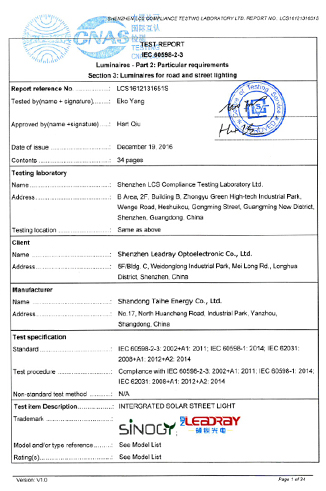

3. Market Delivery Phase: IEC Certification as Access

International Markets: Regions like the EU (CE certification), the Middle East (SASO certification), and Southeast Asia (TISI certification) all require solar street lights to provide proof of IEC standard compliance. For example, EU entry requires CE-EMC + LVD certification.

The LVD (Low Voltage Directive) is based on standards like IEC 61347 and IEC 62133, and requires a test report from an EU Notified Body (such as TUV or SGS).

Domestic Market: Although GB standards exist in China (e.g., GB 7000.1 corresponds to IEC 61347-1), government bidding projects (such as municipal roads and highways) often require products to comply with IEC standards.

This is especially true for projects intended for export and then sold domestically, where IEC certification is a plus.