IES standards cover the entire lighting industry chain. Among them, the standards directly related to solar street lights (which have both "lighting functions" and "new energy power supply characteristics") mainly focus on four dimensions: optical performance, lighting effects, energy efficiency, and reliability.

| Standard Category | Key IES Standards (Examples) | Core control content | The significance of solar street lights |

| Optical performance test | IES LM-79-23 (Solid-State Lighting Product Photoelectric Performance Test) | Specifies the test methods for parameters such as luminous flux, luminous efficacy, color temperature, color rendering index (CRI), and chromaticity coordinates of LED light sources/luminaires. | Whether the optical performance of the core component of solar street lights (LED lamp heads) meets the standards directly determines the lighting brightness and light color stability. |

| Lighting design specifications | IES RP-8-18 (Recommended Practice for Roadway and Parking Lot Lighting) | Clarify the lighting levels (average illuminance, illuminance uniformity, glare limitation) for different road types (main roads, secondary roads, sidewalks). | Provide guidance on the “light distribution design” (such as the angle of the street light lens) and “installation plan” (spacing, height) of solar street lights to ensure that road lighting needs are met. |

| Energy efficiency and energy conservation | IES LM-80-20 (LED light source lumen maintenance test) | It is required to test the lumen attenuation curve of LED light sources at different temperatures to evaluate their long-term luminous efficacy stability (usually tested for 6000/10000 hours). | Solar street lights rely on batteries for power supply, and high stability of light efficiency can reduce energy consumption; at the same time, the lumen maintenance rate determines the "service life" of the street light (avoiding premature dimming). |

| Reliability and Environment | IES LM-66-19 (Environmental Durability Test for Lighting Products) | Includes environmental testing requirements such as high and low temperature cycles, humidity, vibration, dust and water resistance (coordinated with IP rating), etc. | Solar street lights are mostly used outdoors (in harsh environments such as high temperature, heavy rain, sand and dust), and the weather resistance of the products must be verified by this standard. |

[Core Scenarios Related to Solar Street Light Factory Products and IES]

From product development to factory testing and market delivery, IES standards are integrated throughout the entire factory process, providing a core foundation for product competitiveness:

1. Product Development Phase: IES standards are used as the design benchmark.

Light Distribution Design: Based on the lighting requirements for different roads specified in IES RP-8-18 (e.g., average illuminance ≥ 20 lux and uniformity ≥ 0.4 on main roads), the LED lamp head's light distribution curve is adjusted (e.g., "bat-wing" distribution to reduce glare and improve road surface uniformity) to ensure the streetlight lighting meets the scenario requirements.

Light Source Selection: Based on IES LM-79 requirements, LED light sources with a luminous efficacy ≥ 130 lm/W and a CRI ≥ 70 are selected (street lighting requires moderate color rendering but must ensure legibility). IES LM-80 is also used to verify that the light source's lumen maintenance rate is ≥ 90% after 10,000 hours to avoid insufficient brightness after long-term use.

2. Production Testing: Qualification based on IES standards

The factory must establish an optical laboratory that meets IES standards and conduct sampling testing on each batch of products. Key testing items include:

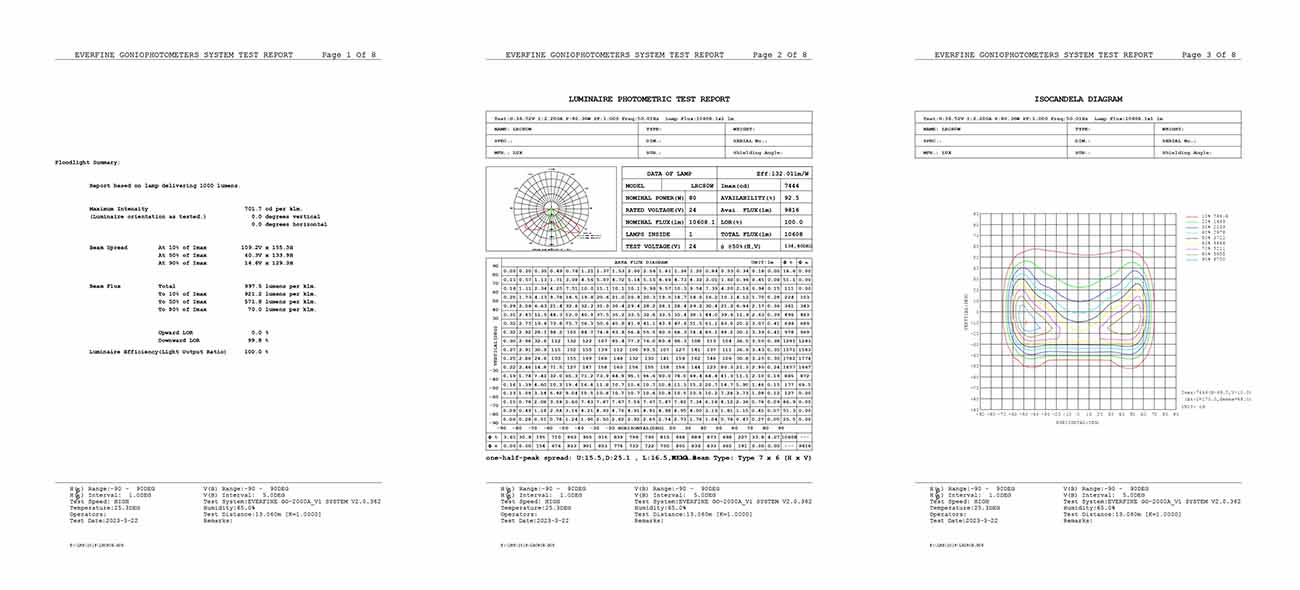

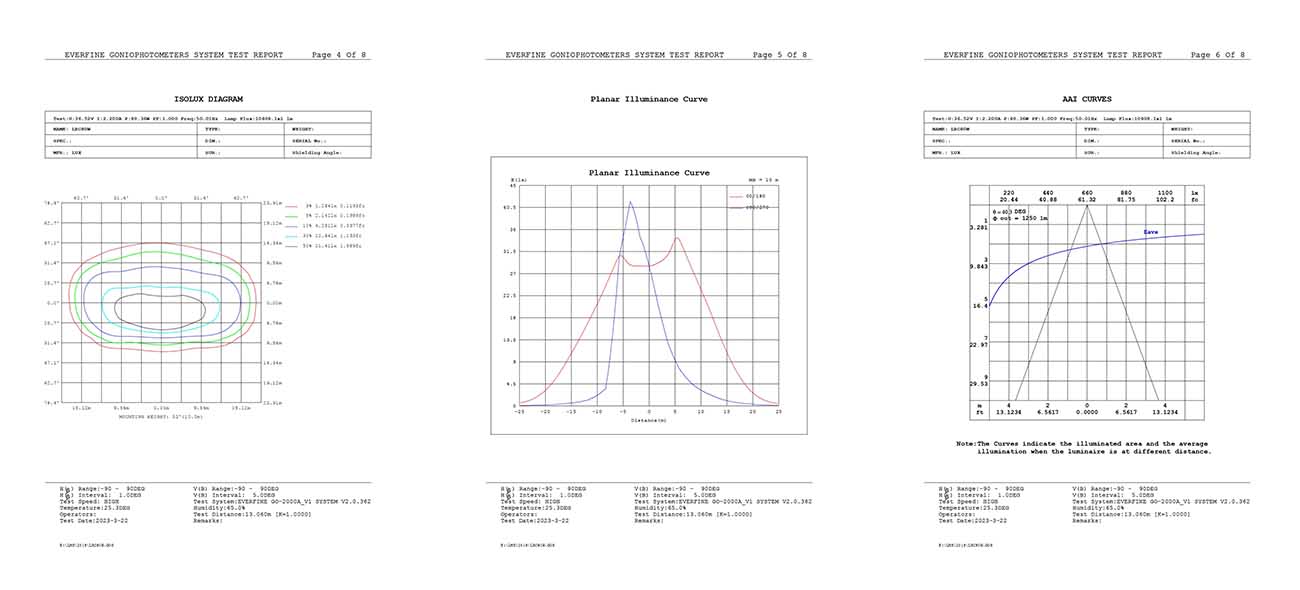

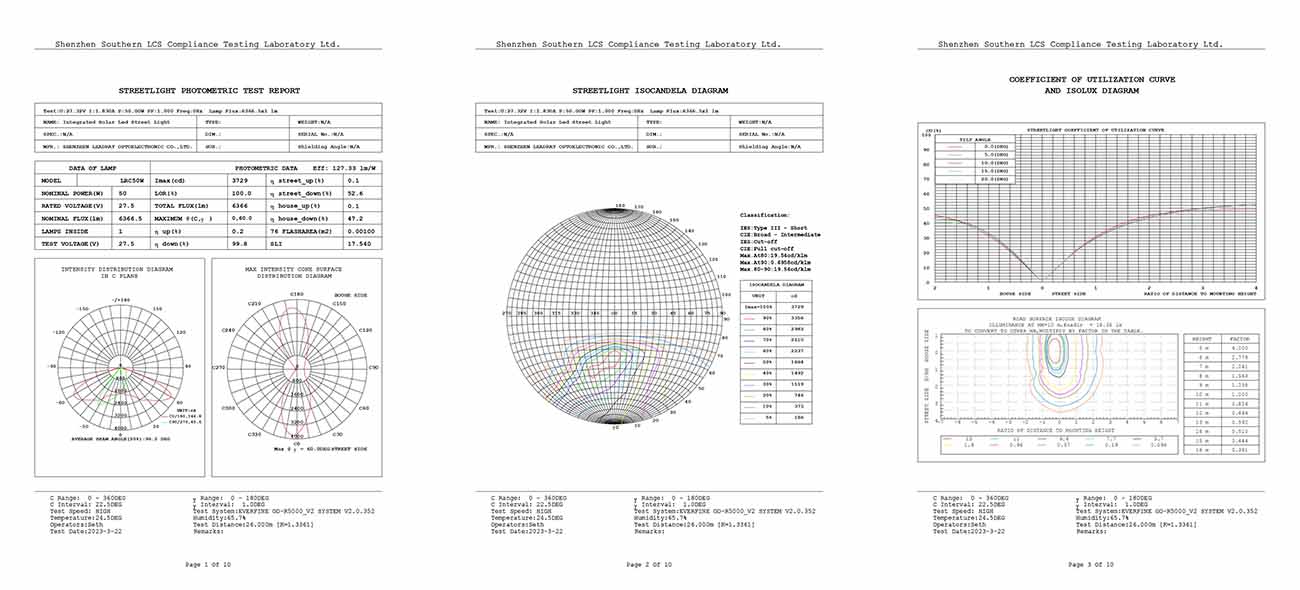

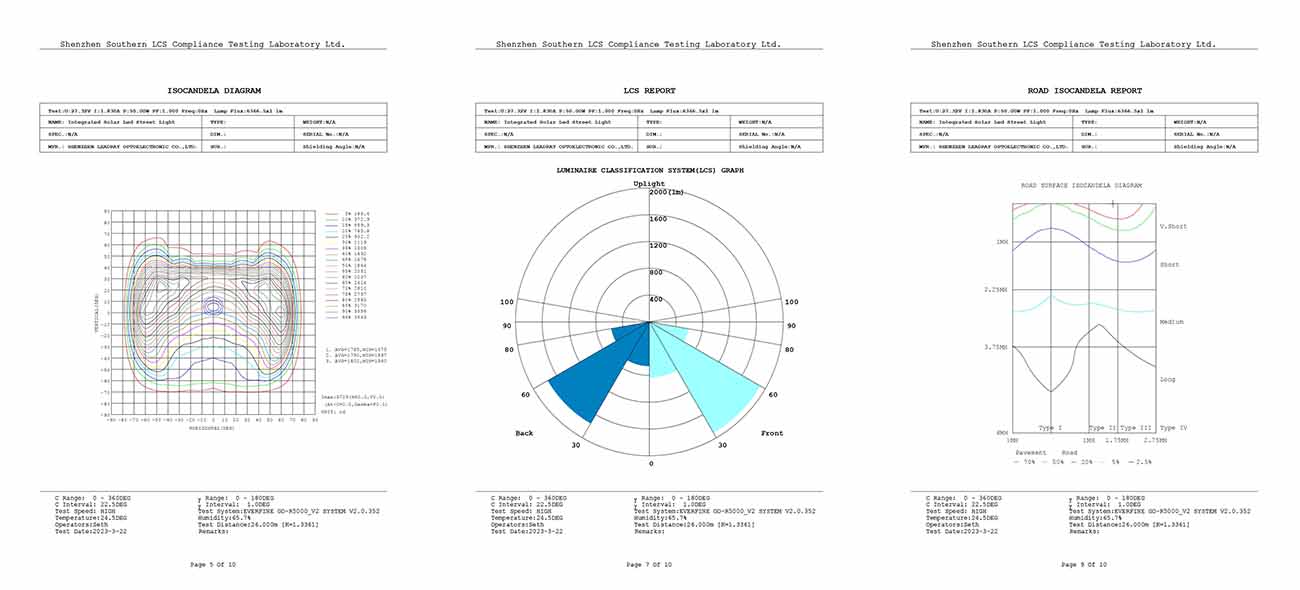

Luminous flux/luminous efficacy testing: Measure the actual luminous flux of the LED lamp holder using an integrating sphere (compliant with IES LM-79) to ensure a deviation of ≤±5% from the design value;

Light distribution curve testing: A goniophotometer is used to plot a light distribution curve to verify that the street lamp's light intensity distribution within the 0°-180° angle meets IES RP-8 road lighting requirements (e.g., vertical illuminance on the road surface ≥ 3 lux, and glare avoidance rating (UGR) ≥ 19);

Environmental durability testing: In accordance with IES LM-66, street lamps undergo a -40°C to +60°C high and low temperature cycling test (50 cycles) and a 95% RH constant humidity test (1000 hours) to verify the reliability of the lamp housing, seals, and internal circuitry.

3. Market Delivery Phase: Using IES as Compliance Certification

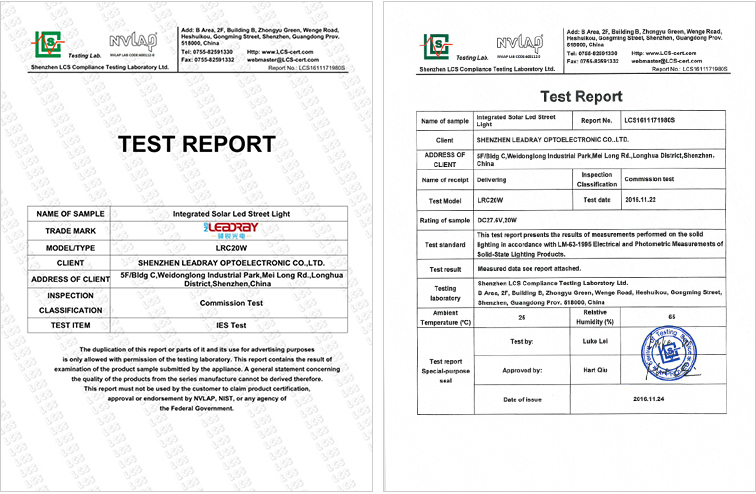

Export markets: Customers in Europe, the United States, Southeast Asia, and other regions typically require solar street lights to provide "IES standard-compliant test reports" (e.g., IES LM-79/LM-80 test reports issued by third-party laboratories such as SGS and Intertek) as a basis for customs clearance and acceptance.

Domestic projects: Tender documents for government road reconstruction, industrial park construction, and other projects often explicitly require street lights to "meet IES RP-8 standards for lighting performance." Factories are required to provide corresponding test reports and design plans to demonstrate that their products meet project requirements.

Implementing IES standards not only meets market compliance needs but also improves product lighting stability, energy efficiency, and outdoor durability through standardized design and testing – the core point for solar street lights to move from “usable” to “easy to use.”

leave a message

Scan to Wechat :

Scan to WhatsApp :