Shandong Taihe Energy Co., LTD (Shenzhen Leadray Optoelectronic) for the solar lighting industry's first military qualified enterprises, in strict accordance with the military standards for the delivery of high quality products

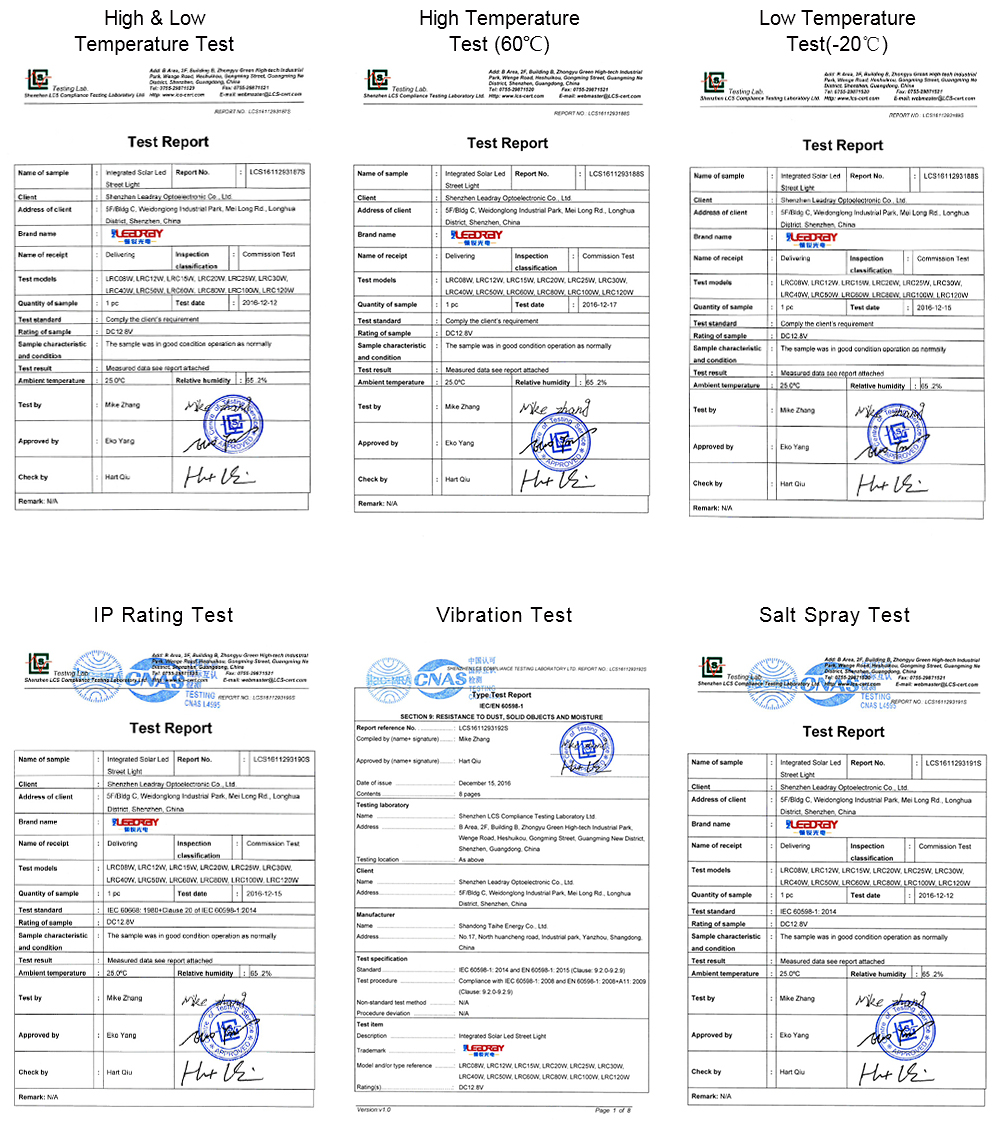

We provie our customers high quality all in one solar street lights, which all have been tested by high-low temperature shock, low temperature, high temperature, shake, IP and salt spray.

【1】Power generation efficiency test: Verify the energy conversion capacity of solar panels

Test method

Under standard test conditions (STC: irradiance 1000W/㎡, temperature 25℃, AM1.5 spectrum), use the "Solar Module Tester" to measure the open circuit voltage, short circuit current, and maximum output power of the solar panel;

Simulate different actual scenarios (weak light: irradiance 500W/㎡, high temperature: temperature 45℃) to test the power attenuation rate of the solar panel.

【2】Environmental Adaptability Test: Verifies the product's ability to withstand harsh outdoor environments

Test Items and Methods

Waterproof Test: The entire streetlight (including the lamp holder, controller, and lithium battery compartment) is immersed in water at a depth of 1 meter for 30 minutes in an IPX7 waterproof test chamber. After the test, the lamp is powered on to check for normal operation.

Salt Spray Test: The lamp pole and solar panel bracket are placed in a neutral salt spray test chamber (5% sodium chloride solution, 35°C) and sprayed continuously for 1000 hours. After the test, surface corrosion is inspected.

Wind Resistance Test: A wind tunnel laboratory simulates a force 12 wind (32.7m/s) and subjects the lamp pole to a 1-hour wind pressure test to check for bending and loose connections.

High-Low-Temperature Cycling Test: The streetlight is placed in a high-low temperature cycling chamber and cycled 50 cycles from -30°C (4 hours) to 25°C (1 hour) to 60°C (4 hours) to 25°C (1 hour). After testing, check the electrical performance and structural integrity.

| Test items | Test phenomenon | Result determination |

| Waterproof test | After soaking, power on, lighting, dimming, and remote monitoring functions are normal, and there is no short circuit. |

Qualified (IPX6) Qualified (IPX7) |

| Salt spray resistance test | After 1000 hours, there is no rust on the surface of the lamp pole and no corrosion or breakage on the bracket. | Qualified (≥1000 hours) |

| Wind resistance test | After a force 12 wind, the maximum bending of the light pole is ≤5mm, and the connectors are not loose. | Qualified (resistant to force 12 wind) |

| High and low temperature cycle test | After 50 cycles, the solar panel power generation efficiency has not decreased, the lithium battery capacity has not decreased, and the controller has not crashed. | Qualified |

【3】Safety performance test: Verify that there are no safety hazards during use

Test items and methods

Anti-electric shock test: Use a "ground resistance tester" to measure the ground resistance of the street lamp (≤4Ω is qualified), and use a "voltage tester" to apply 1500V AC voltage to the power cord and the casing for 1 minute to test for leakage;

Lithium battery safety test: Perform a "needle penetration test" (a 3mm diameter steel needle penetrates the battery cell) and a "compression test" (100kN pressure compression) on the lithium battery to observe whether it catches fire or explodes;

Light pole strength test: Apply a horizontal force to the top of the light pole (calculated according to the wind load corresponding to the height of the light pole) to test whether the light pole breaks or yields.

【4】Energy storage performance test: verify the battery life and life of lithium batteries

Test method

Battery life test: simulate "continuous rainy days" (no sunlight), let the street lights run according to "8 hours of light per day (full light for the first 4 hours and half light for the last 4 hours)", and record the number of days the lithium battery can support;

Cycle life test: use a "battery cycle test cabinet" to cycle "charge to 100% → discharge to 20%", and record the number of cycles when the lithium battery capacity decays to 80%;

Low temperature performance test: test the charging efficiency (time to charge to full charge) and discharge capacity (actual discharge amount / rated capacity) of the lithium battery in low temperature environments of -30℃ and -20℃.

Comprehensive Street Light Test Conclusions

This test covered five core aspects of solar street lights: power generation, energy storage, environmental adaptability, safety, and long-term stability.

All 15 sets of samples passed the test. The test results show that:

Product performance meets national and industry standards, and core indicators (such as solar energy conversion efficiency, lithium battery cycle life, and wind resistance) exceed the industry average.

It is suitable for a variety of scenarios, including rural, municipal, and industrial parks, and can withstand harsh outdoor environments such as low and high temperatures, high salt fog, strong winds, and rainy weather.

It offers reliable safety performance, eliminates potential risks such as electric shock and fire, and offers strong long-term stability with a service life of 8-10 years, meeting customer requirements for high reliability and low maintenance.

leave a message

Scan to Wechat :

Scan to WhatsApp :